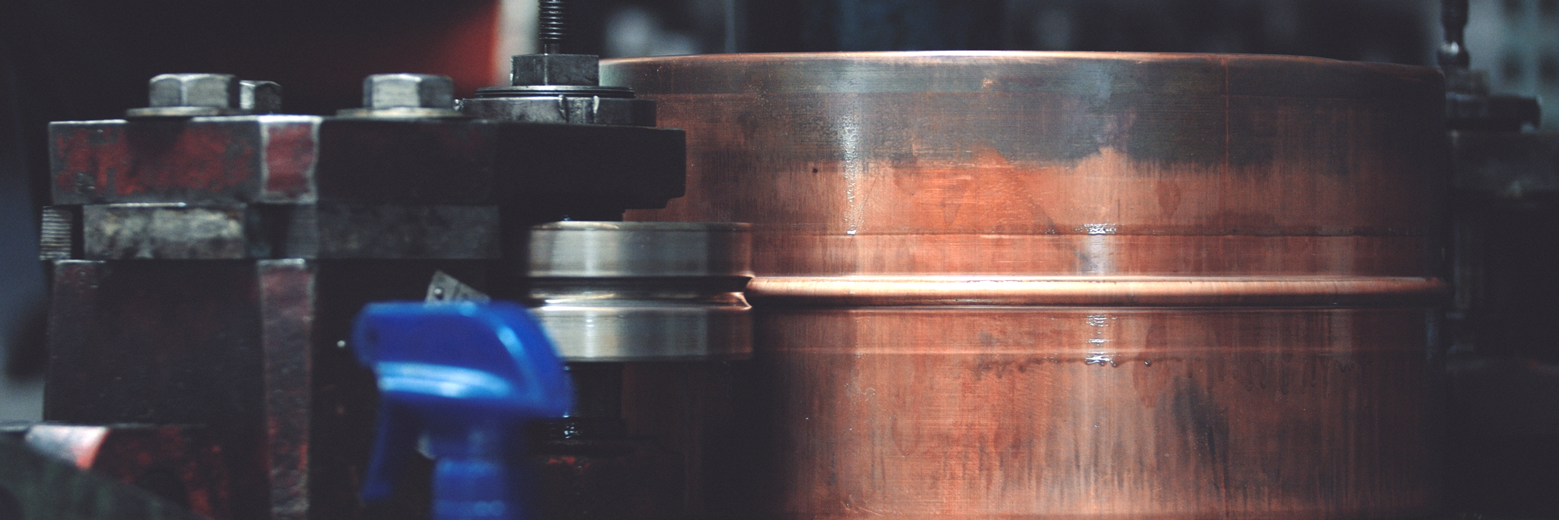

Hi-Craft’s primary area of expertise is the highly specialized process of Metal Spinning. In metal spinning, a flat metal disc is gradually forced by a roller onto a rotating mandrel, taking the shape of the mandrel. This combination of rotation and force shapes the blank into a cone, hemisphere, tube or other circular or cylindrical shape. Metal spinning remains extremely cost-effective today because it requires inexpensive tooling and can be applied to a wide variety of metals. CNC spin lathes are typically used for spinning large quantities, while, for smaller quantities, hand spinning remains the method of choice.

Watch the video below to see our metal spinning process in action. Here we are spinning an aluminum cover.

What are the Advantages of Metal Spinning?

Compared to other methods, Metal Spinning has multiple advantages, including:

- Traditional designs can be formed as one single, seamless piece

- Low production costs

- Versatile control of thicknesses

- Spun products weigh less (since they do not require thick pieces to weld together)

- A single set-up can be comprised of several operations

- Material waste is notably smaller

- Increased tensile/yield strength and hardness

- Seamless spun objects can withstand higher internal or external pressure

- Symmetry around a centerline

- Modifications to forming parameters and part criteria can be achieved quickly and at a lower cost than other methods

What Types of Products are Made by Metal Spinning?

With our state-of-the-art CNC metal spinning machines, our highly skilled technical and artistic teams are able to create and produce prototypes as well as manufacture low & high production orders. There are no limits on what you can create with us. See some of our most commonly manufactured products:

- Household: Lighting fixtures, sinks, urns, vases, funnels, cooking and baking tools, trash bins, flowerpots, bowls, cups, lids, plates

- Industrial: aircraft parts, cylinders, gas cylinders, office fan panels, inlet panels, nose cones, radar calibration spheres, rocket engine parts, automotive parts

- Misc: bells, musical instruments, keychains, sports equipment components, fishing reel components, ashtrays, whirligigs, toy spinning tops, trophy components, flag bases, table bases, satellite/antenna dishes

- Materials: Aluminum, steel, stainless steel, copper, brass, titanium, bronze, nickel, columbium, high tensile, heat resistant alloys, INX, Inconel, Grade 50/Corten, and Hastelloy ?

View our gallery of products and hand spun metal styles here for other ideas and examples.

Hi-Craft’s Metal Spinning Capabilities

- Alloy Steel

- Aluminum

- Brass

- Bronze

- Carbon Steel

- Columbium

- Copper

- Heat Resistant Alloys

- High Tensile

- Inconel®

- Maraging Steel

- Nickel & Nickel Alloys

- Stainless Steel

- Tantalum

- Titanium

Our Spinning Specifications and Capabilities

- 72″ maximum blank diameter

- Will form material up to .250″ (1/4″) thick

- Equipped with both CNC & playback control systems

- Up to 14,000 lbs of forming pressure

- Requires minimum tooling investment

- Suitable for prototype, low & high production orders